West Bridgewater, MA, USA – REXA, the industry leader in electro-hydraulic actuation technology, announces its Electraulic Technology has played a crucial role in the expansion

of a major midstream pipeline, increasing flow to more than 1,000,000 barrels of crude oil per day.

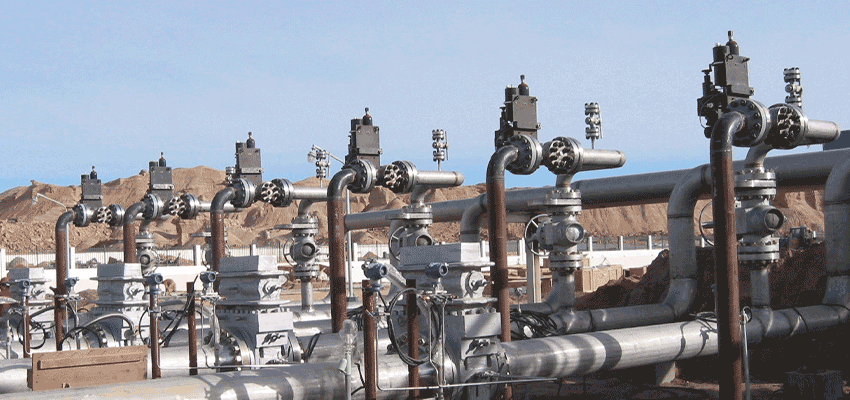

A pipeline company is undertaking several projects to expand its capacity to meet the energy transportation needs of North America. One project involves the modification and upgrading of the existing pump stations, as well as the addition of new pump stations. As part of the expansion project, state-of-the-art pressure control systems are required to assure safe and reliable operation.

The control system must be able to provide a fast response to pressure disturbances during starts, stops, and flow rate changes. It must also provide a fast response to set point adjustments at one station in order to achieve the desired flow rate and pressure at another. To meet this need, the pipeline company, selected REXA’s Electraulic actuators.

Permits have been secured and the expansion is underway, the pipeline company is confident that upgrading the pumping stations and terminals will not only provide the pumping horsepower required along the line, but also the consistent control required of pump discharge pressure to minimize fluctuations of flow and pressure in the line between the stations.

Rigorous customer and third-party testing of the valves and actuator packages provides assurance that the pipeline can be operated close to hydraulic capacity for the increased throughput at 1,000,000 barrels per day.

REXA’s unique Electraulic™ Technology offers unmatched accuracy, repeatability, and reliability, allowing operators to run pipelines closer to hydraulic capacity, which significantly increases throughput and efficiency.