Background on Fluid Catalytic Cracking (FCC)

Fluid catalytic cracking (FCC) is an essential process in refineries, used to convert heavy feedstock oil into valuable gasoline, jet fuel, and diesel, amongst other products. During the FCC reaction coke builds up on the catalyst, limiting the catalyst’s ability to carry out the reaction. The spent catalyst transfers over to the regenerator to burn off the residual coke. As the spent catalyst is regenerated, flue gas (combustion gas) is created by burning off residual coke. The flue gas must then pass through a flue gas slide valve which diverts the flue gas to a power recovery train or through a series of separators and electro-static precipitators before it is released into the atmosphere.

The Importance

The flue gas slide valve provides accurate pressure control of the regenerator, and in turn, control the differential pressure between the reactor and the regenerator. Tight control is critical in maintaining the FCC pressure balance in the cracking process, allowing smooth flow of the catalyst and feedstock oil between the reactor and the regenerator.

Why REXA?

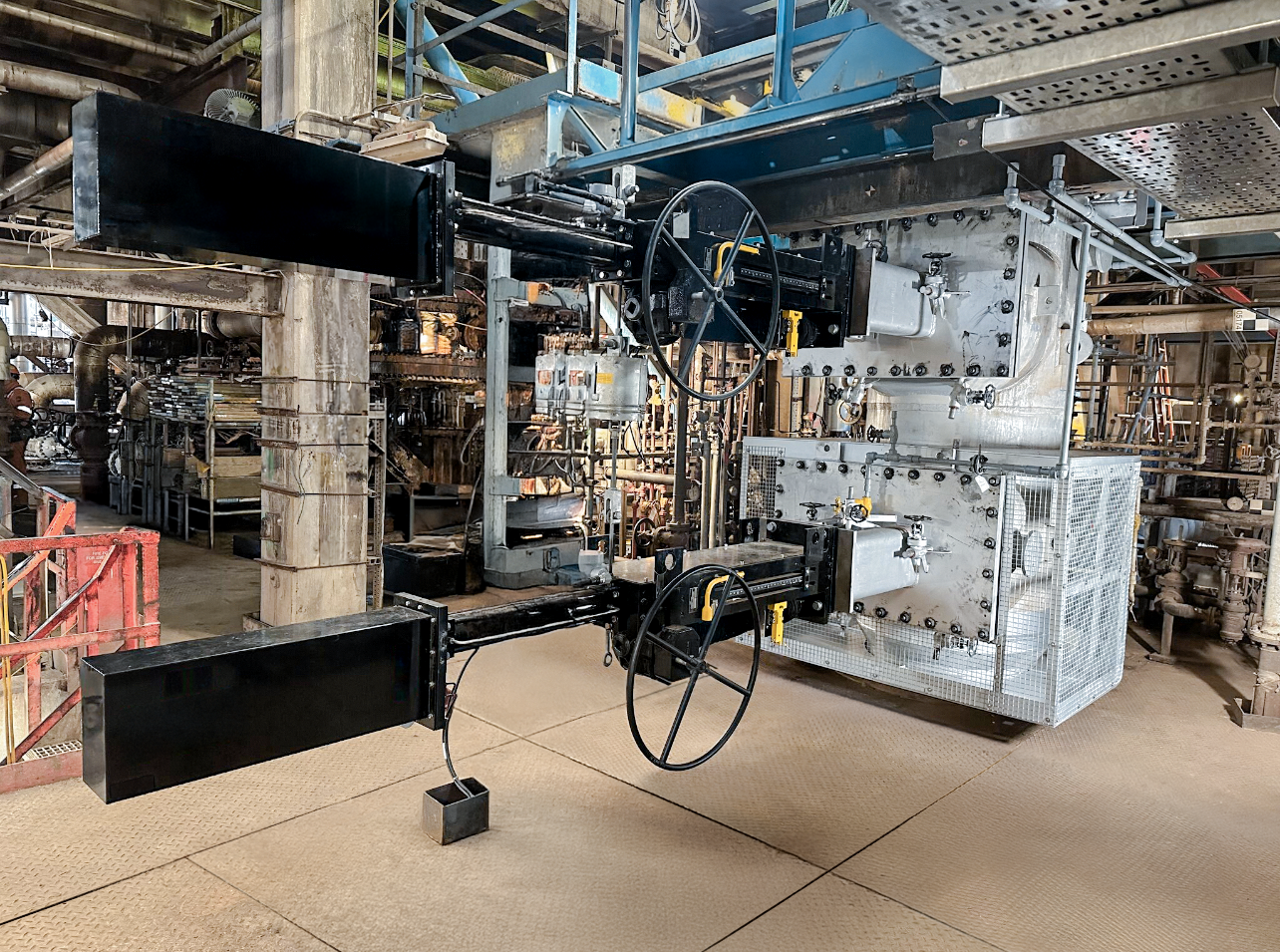

With REXA Electraulic™ Actuation, the end-user gets all the advantages of a hydraulic actuator, such as fast response to signal command and precise modulation of the Flue Gas Slide valve, which are essential for tight control, an efficient process and safe operation.

Literature

Download the full FCC Flue Gas Application Spotlight!