Project Description

Background

Heap leaching is an industrial mining process that consists of the extraction of precious metals from ore through a series of acidic chemical reactions. During this process, the non-valuable earth materials or gangue go through a series of acidic chemical reactions which absorb specific minerals and re-separate them. The main difference between heap leach mining and in-situ mining is the use of a heap pad to separate the ore.

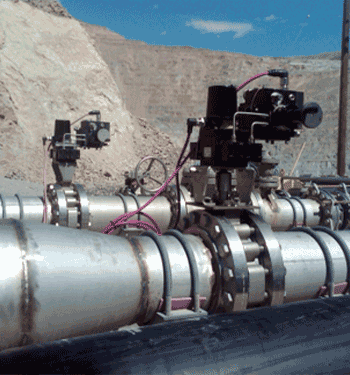

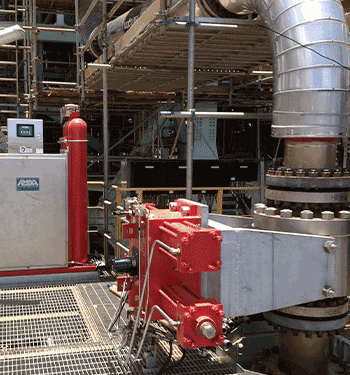

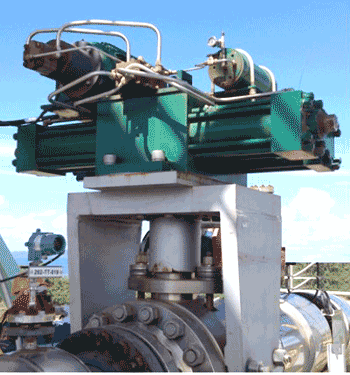

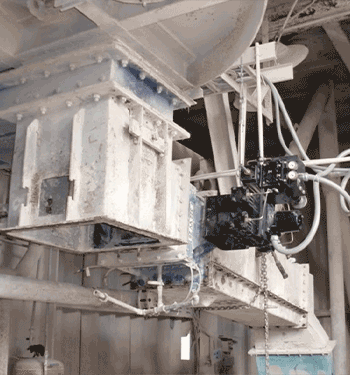

Producing high quality agglomerated ore requires minimal process variation of feed solutions entering the kiln. Tightly-controlled acid feed rates provide stable and predictable agglomerated spheres, therefore leading to less acid consumption and improved leaching. Relying on pneumatic actuators to reliably actuate the ball or globe valve controlling the acid feed flow to the mixer could spell disaster, though.

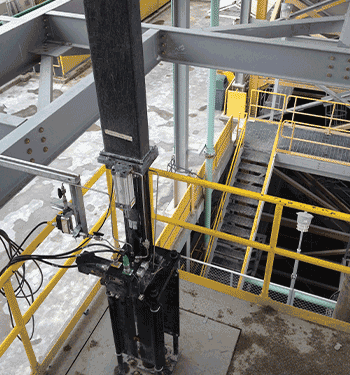

Achieving greater process control is a hallmark of REXA’s Electraulic™ Actuators. Our actuators solve problems with feed rate set-points and variation, resulting in a more efficient process with higher yield. Learn more about the many benefits our actuators provide for heap leaching applications in our full Application Spotlight below!