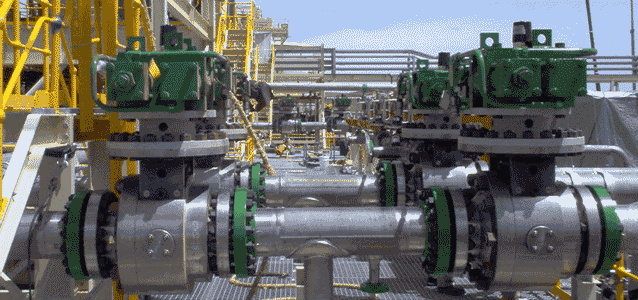

West Bridgewater, MA, USA – REXA, the industry leader in electro-hydraulic actuation technology, announces that two REXA MEGApac Rotary Electraulic™ Actuators have been commissioned into production for slurry isolation control on severe service ball valves at a nickel processing plant in Palawan, Philippines.

These MEGApac Rotary Electraulic™ Actuators, which replaced underperforming pneumatic actuators, are specifically designed to withstand the harsh High-Pressure Acid Leach (HPAL) service – a technology that enables the recovery of nickel metal from laterite ores that traditionally were difficult to process. The MEGApacs use 400,000 in. lbs. of torque and rapid speeds to turn severe service ball valves 90 degrees in under ten seconds for reliable slurry isolation control.

“Slurry Isolation Control is extremely important in the HPAL process. Slurry build-up and insufficient torque cause valve stalls. Stalls can leave the ball edge exposed to the harsh slurry, eroding the ball protective coating. This can result in increased downtime and expensive valve repair costs,” stated Mark Ferra, Mining & Metals Industry Manager, REXA, Inc. “Our MEGApac Rotary Electraulic™ Actuators are built to meet the stringent reliability, high torque, and fast speed requirements for HPAL operational safety and uptime.”

Specifications for the REXA MEGApac Rotary Electraulic™ Actuators include:

· Application use: Slurry Isolation Control

· Mount: severe service ball valve

· Valve Rotation: 90 degrees

· Actuator rate of travel: 90 degrees in under ten seconds

· Actuator rated output: 400,000 in. lbs.

REXA’s unique Electraulic™ Technology is a revolutionary approach to actuation that combines the simplicity of electric operation, the power of hydraulics, the reliability of solid state electronics, and the flexibility of user-configured control. Electraulic™ actuators and drives offer a self-contained, positive pressure, hermetically sealed system that requires minimal power consumption. There are no filters, large reservoirs or routine oil maintenance needed.