Wicket Gates

Background

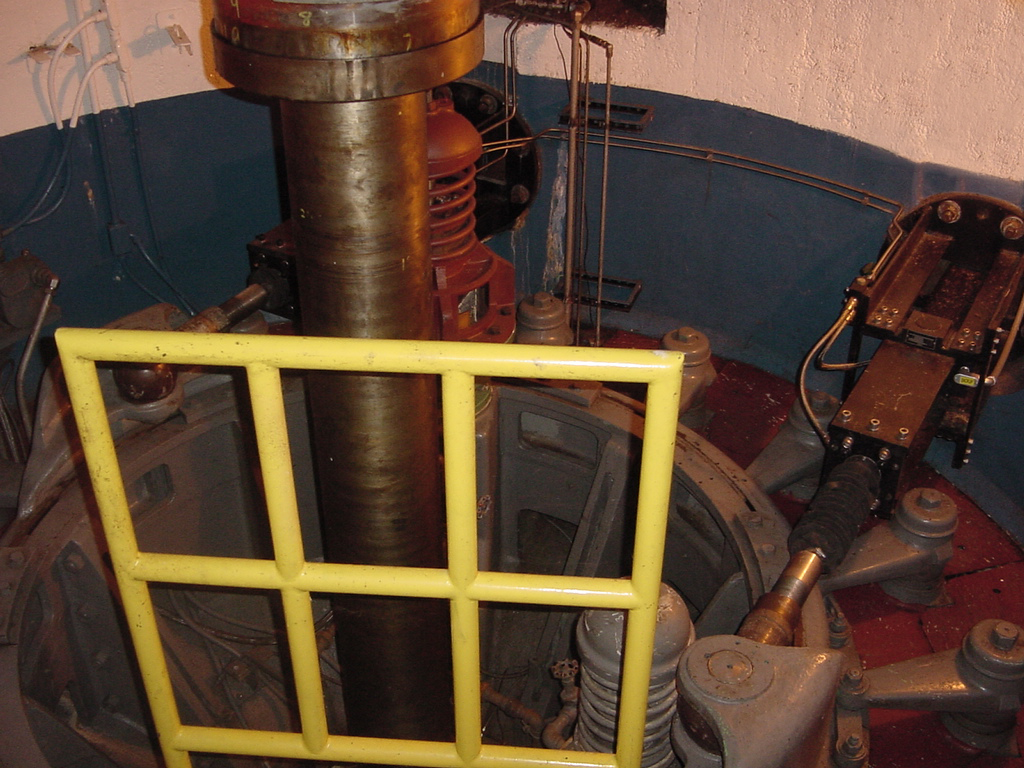

Wicket gates are a series of adjustable vanes controlling the flow of water to a reaction turbine. Each vane, mechanically in parallel, is attached to an adjustable gate ring. Actuating the gate ring either clockwise or counterclockwise positions the wicket gates to regulate water flow to the turbine. Variations of operating the wicket gates are dependent on many factors including axis of the turbine, available head, physical space and turbine type.

A Hydraulic Power Unit (HPU) is one of the most common methods of actuating wicket gates. This allows the supply of pressurized oil to a servomotor, adjusting the wicket gates to a desired position. An HPU system usually includes an oil pressure tank (or accumulator), oil sump, air compressor, oil filtration/condition system, and an oil pump/motor – all coupled with a governor mechanism.

Problem

The degradation of hydraulic fluid can cause problems in the HPU. This can lead to sluggish performance or entirely disable the oil pressure system, therefore causing an increase in downtime and cost.

Another problem lies in the growing concern and awareness on environmental impact. With governments enforcing strict regulations to reduce the hydroelectric industry’s environmental impact, HPU systems are under heavy scrutiny. Protecting waterways is top priority and unfortunately, HPU systems pose higher risk as they contain hundreds (and sometimes thousands) of gallons of oil – increasing the potential discharge into waterways. The consequences of this can be severe, resulting in hefty fines and potential incarceration.

Literature

Download the Wicket Gate Operation for Reaction Turbines Application Spotlight!